Sorter Systems

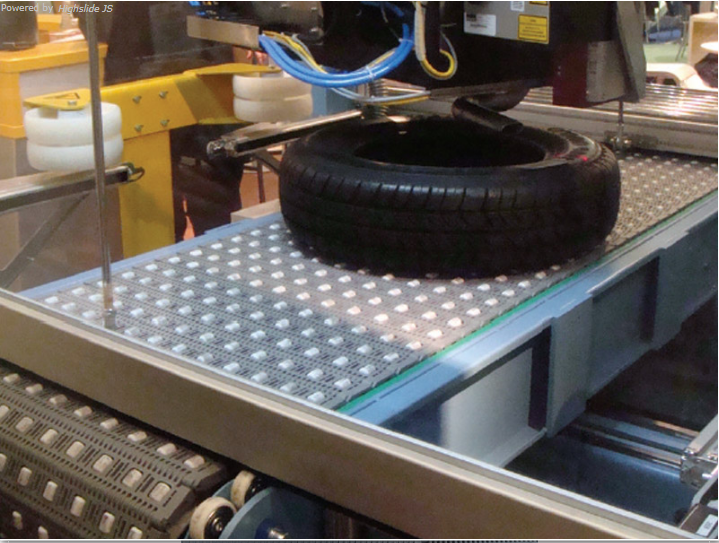

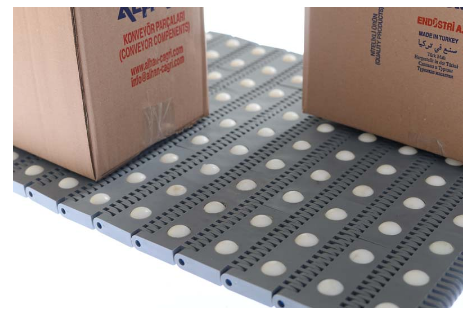

Due to its’ design, 957 Model Transfer Roller Belt moves the items conveyed towards the direction of the line, and it provides transfering of products to in other side of the sytem. This process paves the way for collecting the conveyed items much easier.

These sort of belts are generally preferred by packaging and tire industries.

The main reason of designation of sorter system is to distribute the items according to their features such as weight, barcode, and so on. Building such an automation sytem is automatically reduce the mistakes man-made factors.

Mainly, there are three different model of the roller belts named transfer, acummulation, and sorter respectively. Each of them serves the solutions of different technical designs.

Mainly, there are three different model of the roller belts named transfer, acummulation, and sorter respectively. Each of them serves the solutions of different technical designs.

This sort of systems are not just safer to deliver the items, but also appealing to each budget. Moreover, it increases the productivity, reduces some costs, and also provides the customer satisfaction.

Areas of usage:

1- Preparing an orders

2- Counting of products

3- Barcode Control Systems

Sectors of usage:

1- Textile

2- Automative

3- Health

4- Electronic

Why modular belts shall be preferred instead of roller conveyors in these lines ?

In a conveyor as driven roller, transmission and carrying mechanism are considered as two separate planes. In these processes, movement is providing by either a chain or rollers. Due to meterial fatigue, the pitch of chains are changing after a while and the bearing in the rollers may lose their function. On the other hand, in the systems designed with modular belts, both the transmission and carrying are considered as one. As a consequence, neither it needs a chain, nor a roller.

Besides, life-time of modular belts are way longer than the other systems such as PVC, rubber, and so on. Maintenance of the systems built with modular belts are easier than the others. The spare parts of the modules cannot just be found easily, but also the maintenances of the system built with this type of belts are way easier, because it can easily be demount and assemble.

Besides, life-time of modular belts are way longer than the other systems such as PVC, rubber, and so on. Maintenance of the systems built with modular belts are easier than the others. The spare parts of the modules cannot just be found easily, but also the maintenances of the system built with this type of belts are way easier, because it can easily be demount and assemble.

On the other hand, the systems built by PVC or rubber belts, do not let the localized repairment. Additionally, the belt may vibrate or skid due to lack of a real sprocket. In the short-term, these sort of systems seem cheaper and faster, constructions may cause way bigger problem for the long-term.

Copyright © 2023. Tüm hakları saklıdır.

Phone:+90 (212) 544 50 55

Address: Maltepe Mh. Davutpaşa Cd. Mb İş Merkezi 14/4 Topkapı-İstanbul/Türkiye